What is a Grounding Electrode?

A grounding electrode is simply a conductive object that establishes a direct connection to the Earth.

The NEC lists 8 specific items that can be used.

- The Golden Rule: If any of the first three items (Water Pipe, Building Steel, or Ufer) exist at the building, they MUST be bonded together to form the grounding electrode system.

- If they don’t exist, you must install “Made Electrodes” (like rods or plates).

Category A: Building Elements (Must Use if Present)

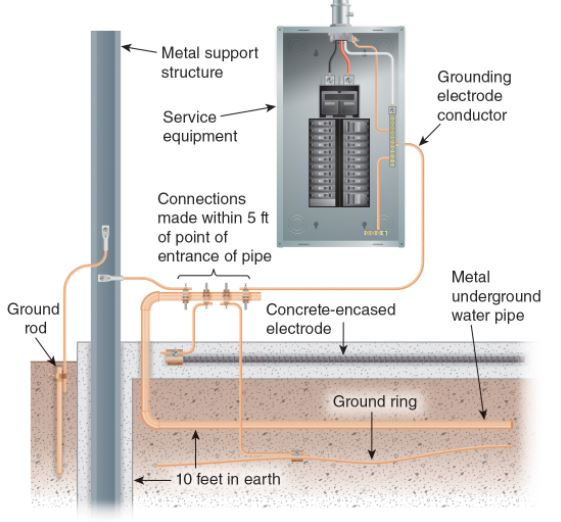

1. Metal Underground Water Pipe

- Requirement: Must have at least 10 feet in direct contact with the earth.

- Continuity: Must be electrically continuous to the point of attachment.

- Crucial Note: A water pipe electrode always requires a supplemental electrode (like a ground rod) because the utility might swap the pipe for plastic (PVC) in the future.

2. Metal In-Ground Support Structure (“Building Steel”)

- Requirement: Must have at least 10 feet vertically in contact with the earth (or encased in concrete in contact with the earth).

- Note: Not all steel frames qualify. If the steel sits on bolts in a concrete footing with no earth contact, it is not an electrode.

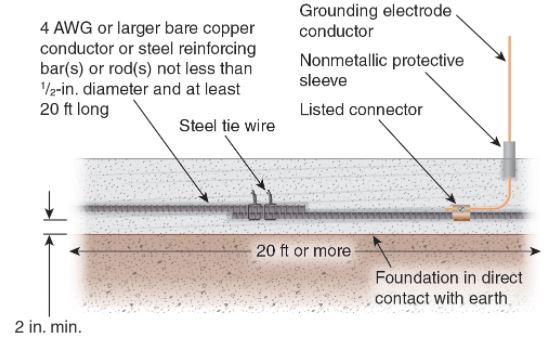

3. Concrete-Encased Electrode (“Ufer”) This is one of the most effective grounds available. It uses the concrete footing to make the connection.

- Method A: 20+ feet of bare copper conductor (min 4 AWG).

- Method B: 20+ feet of steel reinforcing bars (rebar), min ½ inch diameter.

- Installation: Must be encased by at least 2 inches of concrete in direct contact with the earth.

- Exception: In existing buildings, you do not need to disturb/break the concrete to find this if it isn’t already exposed.

Category B: “Made” Electrodes (Installed by Electrician)

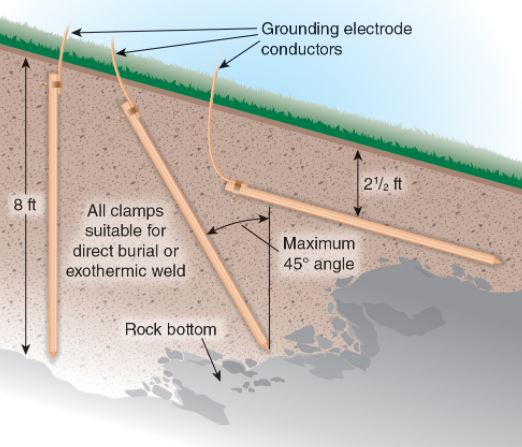

4. Rod and Pipe Electrodes The most common “made” electrode.

- Length: Minimum 8 feet in contact with the earth.

- Type: 5/8″ solid rod OR 3/4″ pipe/conduit.

- Installation: Driven vertically. If you hit rock, it can be driven at an angle (max 45°) or buried in a trench 30 inches deep.

Here is the content for the Grounding Electrode System section of your app.

I have grouped these into “Building Elements” (things already there) and “Made Electrodes” (things you install), as this is how electricians typically think about them in the field.

The 8 Grounding Electrodes

NEC 250.52 Overview

What is a Grounding Electrode?

A grounding electrode is simply a conductive object that establishes a direct connection to the Earth.

The NEC lists 8 specific items that can be used.

- The Golden Rule: If any of the first three items (Water Pipe, Building Steel, or Ufer) exist at the building, they MUST be bonded together to form the grounding electrode system.

- If they don’t exist, you must install “Made Electrodes” (like rods or plates).

Category A: Building Elements (Must Use if Present)

1. Metal Underground Water Pipe

- Requirement: Must have at least 10 feet in direct contact with the earth.

- Continuity: Must be electrically continuous to the point of attachment.

- Crucial Note: A water pipe electrode always requires a supplemental electrode (like a ground rod) because the utility might swap the pipe for plastic (PVC) in the future.

2. Metal In-Ground Support Structure (“Building Steel”)

- Requirement: Must have at least 10 feet vertically in contact with the earth (or encased in concrete in contact with the earth).

- Note: Not all steel frames qualify. If the steel sits on bolts in a concrete footing with no earth contact, it is not an electrode.

3. Concrete-Encased Electrode (“Ufer”) This is one of the most effective grounds available. It uses the concrete footing to make the connection.

- Method A: 20+ feet of bare copper conductor (min 4 AWG).

- Method B: 20+ feet of steel reinforcing bars (rebar), min ½ inch diameter.

- Installation: Must be encased by at least 2 inches of concrete in direct contact with the earth.

- Exception: In existing buildings, you do not need to disturb/break the concrete to find this if it isn’t already exposed.

Category B: “Made” Electrodes (Installed by Electrician)

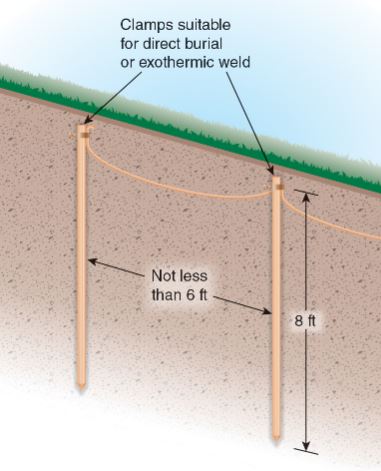

4. Rod and Pipe Electrodes The most common “made” electrode.

- Length: Minimum 8 feet in contact with the earth.

- Type: 5/8″ solid rod OR 3/4″ pipe/conduit.

- Installation: Driven vertically. If you hit rock, it can be driven at an angle (max 45°) or buried in a trench 30 inches deep.

5. Ground Ring A wire that completely encircles the building.

- Size: Minimum 2 AWG bare copper.

- Length: Minimum 20 feet.

- Depth: Buried at least 30 inches deep.

6. Plate Electrodes Used when rods cannot be driven.

- Surface Area: Must expose 2 square feet to the soil.

- Material: ¼” thick if steel/iron; 1.5mm thick if non-ferrous.

- Depth: Buried at least 30 inches deep.

7. Other Listed Electrodes Any other grounding system specifically listed by a testing lab (UL, etc.) for this purpose.

8. Other Local Underground Systems Permitted underground metal structures such as metal well casings or underground tanks (excluding gas piping).

⚠️ Critical Installation Rules

The “Supplemental” Rule

- Water Pipes are not trusted alone. They must be supplemented by another electrode (usually a rod).

- Rods/Pipes/Plates generally require a supplement as well, unless you can prove the resistance to ground is 25 ohms or less (which is rare).

- Standard Practice: Most electricians simply drive two ground rods, spaced 6 feet apart, to satisfy this requirement without testing.

Accessibility Connections to the grounding electrodes must remain accessible (you must be able to see/touch the clamp).

- Exceptions: Connections that are listed for burial (exothermic welds) or concrete encasement do not need to be accessible.