Purpose

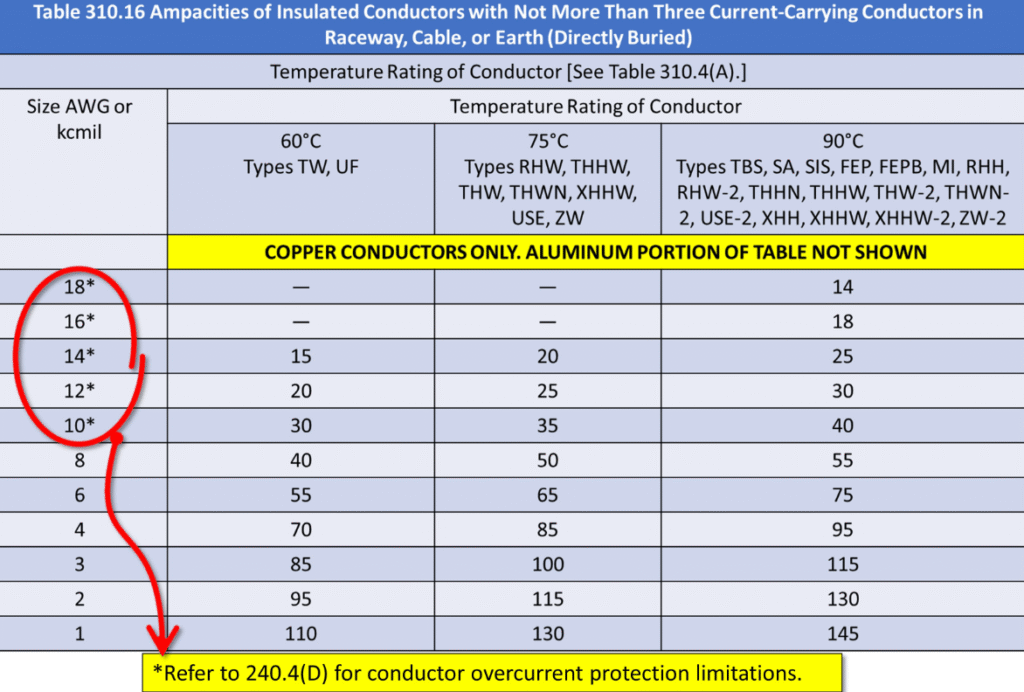

NEC Table 310.16 provides the allowable ampacity (current-carrying capacity) of insulated conductors rated 0 – 2000 volts.

It is one of the most used tables in the NEC — helping electricians size wires safely based on insulation type, temperature rating, and installation conditions.

Understanding the Table

Ampacity depends on several factors:

- Conductor Material – Copper carries more current than aluminum for the same size.

- Insulation Temperature Rating – Common ratings:

- 60 °C (140 °F) for older cables or NM-B.

- 75 °C (167 °F) for THW, XHHW.

- 90 °C (194 °F) for THHN, THWN-2, XHHW-2.

- Ambient Temperature – Table values assume 30 °C (86 °F). Apply correction factors if ambient temperature is higher or lower.

- Number of Conductors – If more than three current-carrying conductors are in a raceway or cable, apply adjustment factors from Table 310.15(C)(1).

- Voltage Drop – Recommended to keep total voltage drop within 3 % for branch circuits or feeders.

The Asterisk “*” in Table 310.16

Some conductor sizes (18 AWG – 10 AWG) are marked with an asterisk (*).

This refers to Section 240.4(D) — the “Small Conductor Rule.”

It limits overcurrent protection, not the ampacity itself.

- 14 AWG Cu → protected by 15 A max breaker or fuse

- 12 AWG Cu → protected by 20 A

- 10 AWG Cu → protected by 30 A

So while a 10 AWG THWN copper wire is rated 35 A per Table 310.16,

the overcurrent device cannot normally exceed 30 A as per 240.4(D).

This distinction is crucial — ampacity defines what the wire can safely carry;

240.4(D) defines how it must be protected.

Example — Copper Conductors (75 °C Column)

| AWG Size | Ampacity (A) |

|---|---|

| 14 AWG | 20 A* |

| 12 AWG | 25 A* |

| 10 AWG | 35 A* |

| 8 AWG | 50 A |

| 6 AWG | 65 A |

| 4 AWG | 85 A |

| 2 AWG | 115 A |

| 1/0 AWG | 150 A |

| 2/0 AWG | 175 A |

| 3/0 AWG | 200 A |

| 4/0 AWG | 230 A |

*Overcurrent protection limits apply per 240.4(D)

⚙️ Key Takeaways

- Table 310.16 gives the base ampacity values for conductors.

- Section 240.4(D) limits breaker or fuse size for smaller conductors.

- Always apply temperature correction and conductor adjustment factors.

- Confirm equipment termination temperature rating (often 60 °C or 75 °C).

- Proper sizing ensures safety, efficiency, and code compliance.