🔌 What is a Separately Derived System (SDS)?

An SDS is a system sourced from something other than a service where there is no direct electrical connection between the source and the service conductors (Art. 100).

- Examples: Most transformers, and generators or UPS units utilizing a transfer switch that opens the neutral conductor.

- Safety Risk: The lack of a direct connection means the SDS is at a different electrical potential (voltage) than other systems, posing a shock and fire hazard during a fault. The NEC addresses this through specific grounding and bonding rules.

🔗 Key Bonding Components

Proper grounding relies on two critical jumpers to create a low-impedance path for fault current, ensuring overcurrent devices operate quickly.

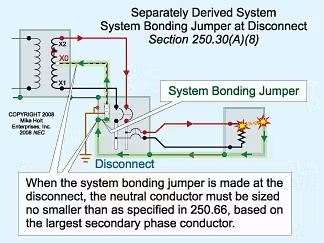

1. System Bonding Jumper (SBJ)

The SBJ (conductor, screw, or strap) bonds the metal parts of the SDS enclosure to the system neutral point (250.2).

- Function: Provides the low-impedance path from metal parts back to the power supply to clear a ground fault by tripping the overcurrent device.

- Critical Rule: You must only install one SBJ. Installing more than one causes objectionable neutral current to flow on conductive metal parts (piping, steel), creating hazards (250.30(A)(3)). Therefore, you cannot have a neutral-to-case connection on the load side of the SBJ.

2. Equipment Bonding Jumper (EBJ)

An EBJ must connect the metal parts of the SDS to the neutral conductor at the disconnecting means.

- Sizing: Where the EBJ is wire type, size it per NEC Table 250.66, based on the area of the secondary conductor in the raceway (250.102(C)).

🌎 Grounding Electrode Conductor (GEC)

The GEC connects the neutral terminal of the SDS to a grounding electrode.

- Origin Point: The GEC must originate at the same point on the SDS where the System Bonding Jumper (SBJ) is connected (250.30(A)(1)) to prevent objectionable neutral current.

- Termination Location: The GEC can terminate to the neutral conductor either at the SDS or at the system disconnecting means, but you cannot do both (250.30(A)(3)).

- Sizing: Size the GEC per NEC 250.66, based on the area of the secondary conductor.

- System Grounding Benefits: This grounding reduces overvoltage from lightning induction and helps reduce voltage stress on electrical insulation, extending equipment life.

Requirements for Multiple SDSs

For multiple SDSs, you can connect the neutral terminal of each derived system to a common GEC.

- The common GEC must be sized no smaller than $3/0 \text{ AWG}$ copper.

- GEC taps must be made at an accessible location using listed connectors, listed bus bars, or exothermic welding.

🪨 Grounding Electrode Requirements

The grounding electrode must be installed as close as possible to the SBJ location. Acceptable electrodes include (250.30(A)(7), 250.52(A)):

| Electrode Type | Key Requirements |

| Metal Water Pipe | Must meet requirements of 250.52(A)(1). |

| Structural Metal | Structural steel of the building/structure. |

| Concrete-Encased | $\ge 20 \text{ feet}$ of steel rebar ($\ge 1/2 \text{ inch}$ diameter) or $4 \text{ AWG}$ wire, encased by $\ge 2 \text{ inches}$ of concrete, in contact with earth. |

| Ground Ring | Encircles the structure, buried $\ge 30 \text{ inches}$ below grade, consisting of $\ge 20 \text{ feet}$ of bare copper conductor $\ge 2 \text{ AWG}$. |

| Ground Rod | Must have $\ge 8 \text{ feet}$ of contact with the soil. If resistance is $> 25 \text{ ohms}$, a second rod must be driven $\ge 6 \text{ feet}$ from the first. |

🛠️ Bonding Metal Parts (Steel & Pipes)

To eliminate hazardous differences of potential (voltage), structural steel and metal piping in the area served by the SDS must be bonded to the neutral conductor at the SDS (250.104(D)).

- Hazard: Failure to bond creates a voltage difference between the SDS and the conductive building components, risking fire and fatal electric shock during a fault.