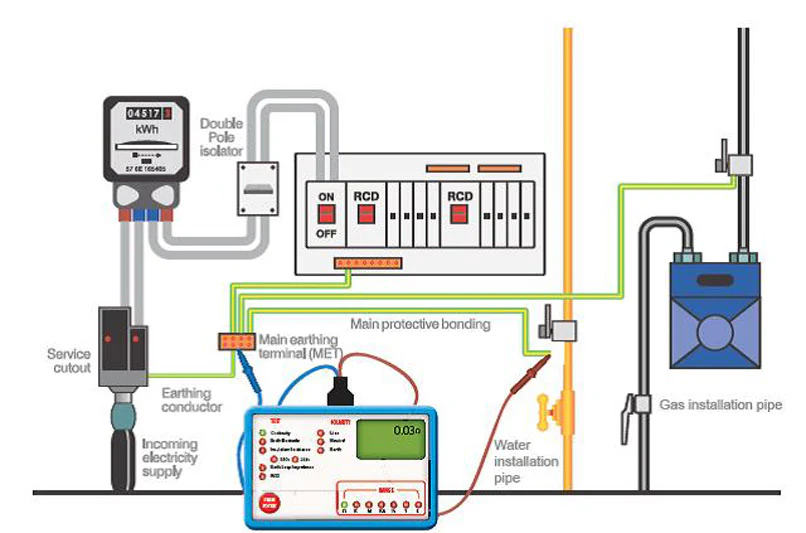

What is Earthing and Bonding?

- Earthing: Connects electrical systems to the ground, providing a safe path for fault currents. Prevents shocks by directing excess electricity into the earth.

- Bonding: Connects all exposed metallic parts together to keep them at the same potential, reducing shock risks.

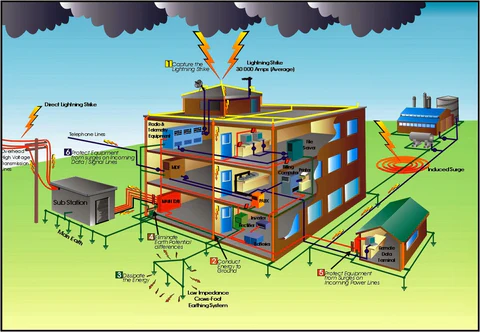

Why Earthing and Bonding are Crucial

- ⚡ Protection from Electric Shock – redirects fault currents safely to ground.

- 🔧 Equipment Safety – prevents damage from surges or stray currents.

- 🔥 Fire Prevention – reduces overheating and sparks that can cause fires.

- 🔗 Harmonized Potential – bonding keeps all metal parts at equal voltage, preventing shock from voltage differences.

Key Testing Methods

- Earth Continuity Test – checks all conductors are connected properly to earth. (Resistance should be very low).

- Earth Resistance Test – measures earth electrode’s ability to dissipate fault current. (Ideal: <10 ohms).

- Insulation Resistance Test – ensures no current leakage through insulators. (Minimum: >1 MΩ).

- Bonding Resistance Test – checks bonding between metal parts. (Should be close to 0 Ω, max 0.2 Ω).

Verification & Maintenance

- 🔍 Visual Checks – connections secure, no corrosion.

- 🧪 Periodic Testing – scheduled tests to detect degradation.

- 📑 Documentation – keep records of results and fixes for compliance.

Common Mistakes to Avoid

- Using poor-quality conductors or electrodes.

- Skipping maintenance – earthing degrades over time.

- Ignoring local electrical standards and regulations.

✅ Conclusion

Earthing and bonding are vital for every electrical installation. They protect people, equipment, and property, while preventing fire and shock risks. Always follow proper testing and maintenance to keep systems safe and compliant.